Metakaolin МKZL

-

Quality

-

Normative documents

-

Use

Metakaolin МKZL (Metakaolin Zhuravliniy Log)

Metakaolin МKZL — amorphous aluminum silicate obtained at thermal processing of enriched kaolin from the Zhuravliniy Log deposits.

The company produces three brands of metakaolin with whiteness being their distinguishing feature.

Whiteness parameters

- Whiteness parameters (color coordinate L* CIELAB (lightness) according to (ISO 787/1) (C/2°)): for МKZL -1 — 97–94,5%, for МKZL -2 — 95–93%.

- МKZL -3 metakaolin has a distinct cream tone color.

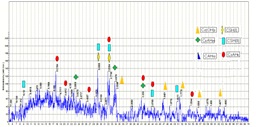

The mineralogical composition

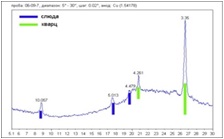

The mineralogical composition of metakaolin MKZL is represented by fully amorphized kaolinite (90-93%), the crystalline phase is represented by relict glist (2.5-3.0%) and quartz (4-5%), crystalline growths (mullite, cristabolite) are almost absent. The degree of amorphization of kaolin indicator value is determined by the absence of the maximum reflection of kaolinite and mullite in the diffraction patterns.

|

|

| micrograph of metakaolin MKZL | diffraction pattern of metakaolin MKZL |

Chemical composition of metakaolin MKZHL

|

Al2O3 |

SiO2 |

Fe2O3 |

TiO2 |

K2O |

Na2O |

CaO |

Losses at calcination |

|

|

Mass content, % |

42–43 |

53–54 |

0,4–0,8 |

0,3–0,5 |

0,8–1,1 |

0,05 |

0,15 |

Up to 1,5 |

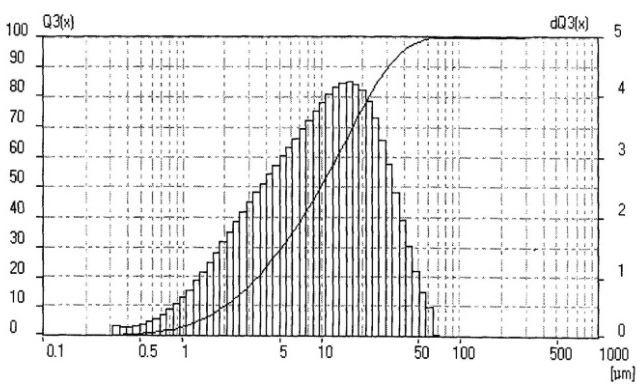

The granulometric composition

|

Residue ratio on the sieve: № 0080 — no more than 0,4%, № 0040 — no more than 5,0% |

Particle distribution, um |

|

|

| Median diameter d50 less than 10 um |

- (рН) Hydrogen-ion concentration 10% — water suspension, 5–6

- Specific surface area is not less than 16500 сm³/g

- Bulk density 0,25–0,3тн/м3.

- Pozzolan activity is not less than 1400 mg Са(ОН)2 / 1 g of metakaolin

Metakaolin МKZL cement stone structure modifier

Metakaolin МKZL in cement

Metakaolin МKZL in dry building mixes

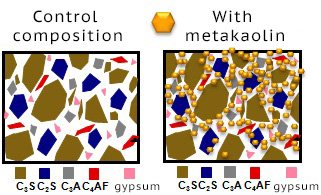

Metakaolin МKZL cement stone structure modifier

Metakaolin is a

|

residue ratio on the sieve: № 0080 — not more than 0,4%, № 0040 — not more than 5,0% |

|

|

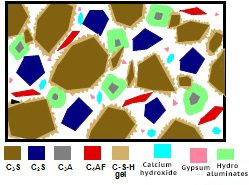

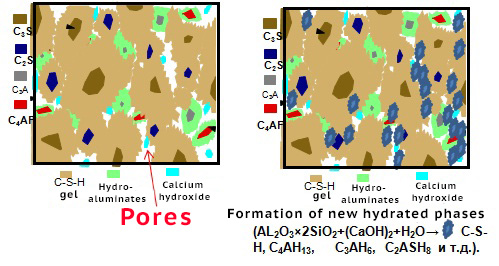

Due to the high specific surface area and laminar morphology of the average size particles d50 = 10 um, metakaolin fills the intercement space; its appending into the |

||

| Cement hydration — a couple of hours later (portlantid emission) |

|

The mineral component of metakaolin comprises highly active aluminate and silicon containing substances. The aluminate component of metakaolin highly increases strength and flexure in the early stages of hardening of the cement composition; the active alumina forms stable hydroaluminates, hydrogarnets. |

|

Cement hydration — after 28 days |

The silicon component of the additive ensures durability of the material by means of regulating the structure formation by changing the alkaline medium. |

|

| Without metakaolin |

With metakaolin |

|

|

|

||

Metakaolin МKZL in cement

The introduction of metakaolin MKZL additive:

- increases the specific surface area of the cement stone up to 40%

- reduces the porosity of the cement stone up to 30%

- the content of calcium hydroxide in the cement stone structure is reduced up to 70% in comparison to the plain cement, which is due to the pozzolanic properties of metakaolin

- with an additive the cement stone structure is more homogenous and dense

|

|

|

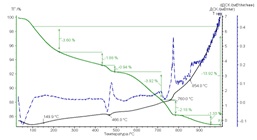

Derivatographic analysis of the cement stone with metakaolin additive |

- According to the DTA data, when introducing the additives hydride phases with an increased content of chemically bound water are forming.

- XRF analysis confirmed the active reduction of calcium hydroxide content in the cement stone in case of the introduction of additives; the formation of low basic hydrate phases. A falloff in intensity and almost disappearance of the peaks belonging to S3S d/n = 3,02Å and β-S2S d / n = 2,87Å confirms the activation of the hydration of the major minerals and cement respectively.

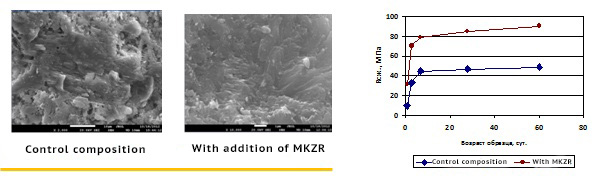

The cement stone structure and the effect of metakaolin on the strength properties of concrete in normal conditions

Metakaolin MKZL in concrete

Getting 70% of the grade strength of concrete in the first day of hardening.

By the third day of hardening, the strength exceeds 50% in relation to the grade strength of concrete (plain concrete gaining 70% of grade strength)

In grade age of CONCRETE (28 days):

- With metakaolin additive the grade strength is 2 times stronger compared to the plain composition.

- increase of sulphate resistance

- Waterproof W20 and higher;

- Mark on frost resistance up to 1,000 cycles or more (up to 400 or more for road concrete).

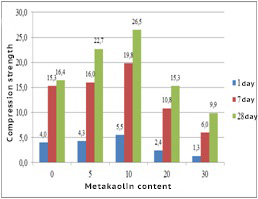

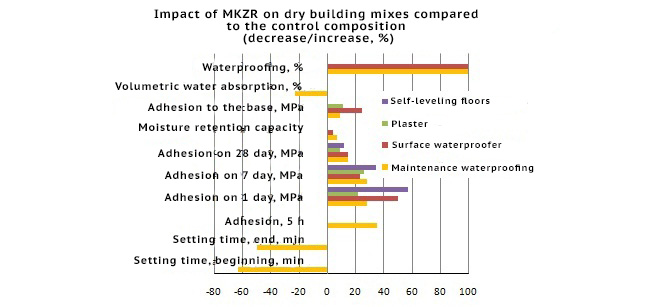

Metakaolin МKZL in dry building mixes

The maximal strength enhancement is recorded for the composition in which the degree of Portland cement substitution by metakaolin MKZL is 10%. Strength enhancement after (7–28) days of hardening is (30–60) % compared to the plain cement.

Metakaolin МKZL an active aluminosilicate pozzolanic additive.

Metakaolin chemically reacts with calcium hydroxide (portlandite) resulting in

For mortar mixes with a metakaolin MKZL additive it is most effectively to use

- The introduction of metakaolin MKZL provides an increased

water-holding capacity of waterproofing solutions ~ 7% without introducing a specialwater-retaining additive. - The introduction of metakaolin MKZL into dry mixes leads to the strength enhancement at different stages of hardening in (20–50) %.

- The introduction of metakaolin MKZL into dry mixes leads to the strength enhancement at different stages of hardening in (20–50) %.

- The introduction of metakaolin MKZL increases water resistance of waterproofing repair compositions.