Enriched kaolin

Enriched kaolin is dispersed pulverized powder (humidity 1.5%) or briquettes (16-18% moisture).

-

Quality

-

Normative documents

-

Use

Mineral composition

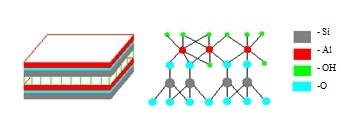

Kaolin — white clay, consisting of the kaolinite mineral. Formed due to the destruction (weathering) of granites, gneisses and other rocks containing feldspars (primary kaolins). Kaolinite structure is composed of layers or sheets of tetrahedral SiO4 constructed from tetrahedrons, and octahedral AlO6. The combination of layers forms an elementary package; the combination of n elementary packets forms a kaolinite plate.

Structure of enriched kaolin

The actual dimensions of kaolinite plates are usually from 0.1 to 3.0 µm; thickness is 0.05 to 2 µm. The presence of hydroxyls on the basal surface of the kaolinite package creates conditions for good wetting with water, but the water molecules in a small amount may be presented between the packages, especially in poorly crystallized kaolins, and the average thickness of the package reaches 7.2 A, which is typical for kaolins of Zhuravliniy Log deposits, which has a poorly crystallized structure.

Zhuravliniy Log kaolin concentrate is characterized not only by the presence of the main

|

Montmorillonite (smectite) as an independent mineral phase was not found, but the background increase in |

| Diffractogram of enriched kaolin |

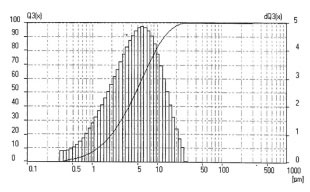

Granulometric size composition

|

Enriched kaolin of Zhuravliniy Log deposits is a powder with particle content of less than 20 µm of about 90%, and the content of particles of less than 2 µm in the range of 40–60% depending on the grade of kaolin. |

| Distribution curve of enriched kaolin particles, µm |

Rheological properties

According to the fire resistance, kaolin belongs to highly refractory clays, the melting temperature of 1750- 1800 °C and above.

The agglomerating degree of kaolins depends on the content of alkaline components (K2O+Na2O). Water absorption of normal kaolins at calcination temperature of 13500С (containing K2O to 1.5%) is 5–7%; the shrinkage (reduction in volume) is 14–15%, for alkaline kaolins: water absorption rate of 1.5–3%, shrinkage rate of 15–16%.

According to the classification of clays by the plasticity index, kaolins belong to the group of stiff clays with the plasticity index of 5–7. At the same time, kaolins have high mechanical strength in the dried state of 2.2–3.5 MPa, in the calcined state (at temperature of 13500С) of 100–120 MPa. Kaolins of Zhuravliniy Log deposit belong to the group of

Kaolin color either in raw or calcined state depends on the mineral composition and the presence of various impurities. According to the color of the calcined crock, kaolin of Zhuravliniy Log belongs to

Chemical composition of enriched kaolin

|

AL2O3 |

SiO2 |

Fe2O3 |

TiO2 |

K2O |

Na2O |

CaO |

Losses at calcination |

|

|

Content, % |

36–38 |

46–48 |

0,4–1,2 |

0,3–0,6 |

0,7–1,5 |

0,05–0,1 |

0,1–0,2 |

13–13,7 |

Enriched kaolin has a Mohs hardness of 1–1.5; specific gravity of 2.58–2.60 g/cm3; volumetric weight (kaolin powder) of 0.25–0.3 g/cm3.

Changes during firing

Heating to 650–700°C (low temperature calcination) removes structural hydroxyls; that results in creation of amorphous metakaolin. During the process, specific gravity of kaolin falls from 2.58 to 2.50, while the firmness, porosity, and, consequently, brightness and whiteness are decreased; light scattering and oil absorption are increased. Upon further heating metakaolin goes over (at temperature of 925–950 °C) into alumosilicic spinel, which goes over into mullite impured with cristobalite when the temperature is further increased. Fully calcined kaolin with maximum brightness and light scattering is obtained by heating to 1000–1150 ° C. This is a sufficient temperature for destruction of the amorphous structure, but without the mineralogical transformation into mullite, while the specific gravity rises to 2.6–2.7, Mohs hardness rate is 6–7.

More information at our website: mixture of kaolin and quartz and premix of Zhuravliniy Log deposit.

Technical condition

Dry-enriched kaolin of Zhuravliniy Log deposit

Enriched kaolin for the ceramics industry

Enriched kaolin for the paper industry

Enriched kaolin of Zhuravliniy Log deposit

A highly dispersed

High rates of brightness both in the dried and calcined state, fire resistance and chemical inertness, low dielectric coefficient, high alumina content (37–38%), the ability to acquire firmness after calcining — it is just a

Enriched kaolin is used in many industries: in ceramics industry for manufacturing of porcelain and faience products, in electrical engineering (insulators), in the industry of refractory products, in paper industry, in cable industry, in rubber industry, in plastic industry, in chemical industry, in perfume industry (as a filler).

Dry separation kaolin of Zhuravliniy Log deposit TU 5729-089-00284530-00

Type KZhV;

GOST 19608–84

Type

Fillers for paints, building mixtures for various purposes. Fillers for rubber and plastic products. Kaolin clays are generally divided into firm and soft, according to the terminology originating from the rubber industry. Firm clays — relatively poorly crystallized, very

Enriched kaolin for ceramics industry TU 5729-090-00284530-00

Type

Grades of kaolin with low iron oxide content and a high content of alumina oxide are an ideal raw material for the production of glass fiber.

In the chemical industry, kaolin is used to give aluminum sulphate, alumina, ultramarine, catalysts for a number of chemical processes (hydrocarbon cracking, etc.), and serves as the carrying agent and filling material of fertilizers and insecticides.

Enriched kaolin for paper industry TU 5729-091-00284530-00

Types